Time:2023-01-06 14:08:56

We help you built your project

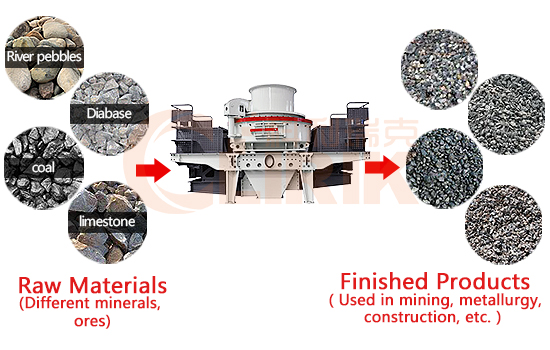

Limestone is characterized by wide distribution in nature, easy mining, low hardness and brittleness, etc. It is an ideal ore for processing sand and gravel. Therefore, how to process limestone into sand and gravel and whether it can be used in concrete has always been a very hot topic. , this article will conduct a detailed analysis from the aspects of limestone crushing/sand making process and concrete sand and stone standards.

After the successful acquisition of limestone mining rights, it is necessary to go through the formalities of processing sand and gravel, including business license, safety approval, tax registration, etc., and then choose a suitable factory site, which should meet the conditions of convenient transportation, water and electricity, and then build the foundation Facilities, cement platform, workers' dormitory, etc., followed by equipment and design process;

The particle size of limestone mined by excavation and blasting is generally about 80 cm to 1 m2. If you want to process it into sand and gravel for concrete, that is, machine-made sand with a particle size of ≤4.75mm and a particle size of 10-20mm, 15 -30mm 12/13 stones need to be crushed, sand made, screened and other technological processes.

Feeding: Put the material on the vibrating feeder by the excavator or the silo, and then feed it into the coarse crusher evenly and continuously;

Crushing: Jaw crusher and impact crusher are responsible for primary crushing and secondary crushing, and there is a conveyor in the middle to transport materials back and forth;

Screening: The vibrating screen is responsible for screening and controlling the particle size of the finished product. If the stone does not meet the particle size of the screen, it will return to the crushing process.

Sand making: part of the crushed limestone is directly sent to the stockpile as a finished product, and the other part is crushed and sand-made by the sand making machine;

Screening: The vibrating screen is also responsible for distinguishing the finished products with different particle sizes, and then returns the unqualified sand to make sand again, and the qualified sand is transported to the sand washing stage by the conveyor;

Sand washing: The sand washing machine (fine sand recycling machine) is responsible for removing the impurities mixed in the finished product, improving the quality of the sand, reducing the mud content, stone powder content, etc.

The main limestone processing equipment is jaw crusher, impact crusher, sand making machine and sand washing machine, and the auxiliary equipment is feeder, vibrating screen, conveyor, etc.

Note: In addition to the above two production processes, limestone can also be ground by a mill after crushing and sand making. After being made into stone powder, it can be used as stone powder for plastering walls, additives for asphalt mixing plants, etc.

ALL RIGHTS RESERVED ? CLIRIK technology and cloud computing service support-91 Internet